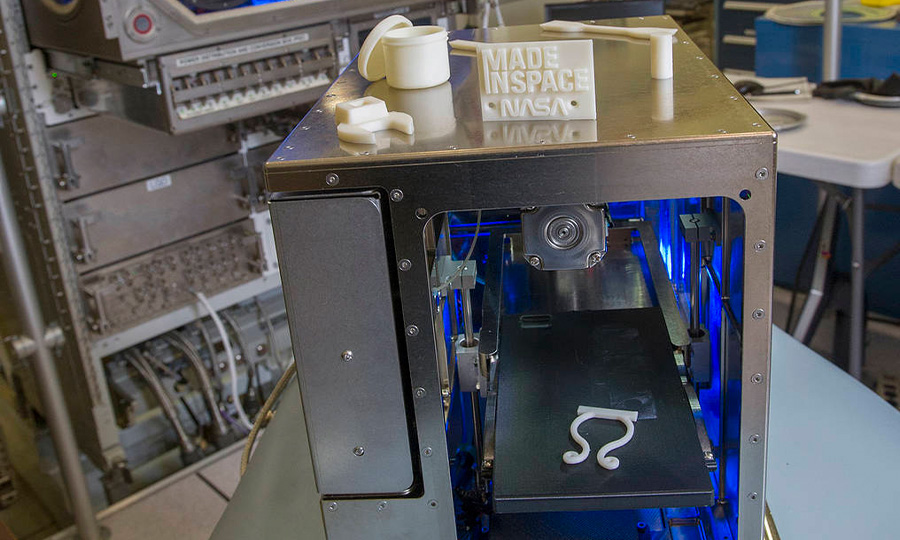

In 2014, NASA achieved a major milestone in space exploration by sending a groundbreaking 3D printer, developed by Redwire, to the International Space Station (ISS). This impressive feat allowed astronauts on the ISS to set up the 3D printer onboard, enhancing their capabilities in space.

The International Space Station gracefully orbits Earth at a height of 390 kilometers, zooming through space at a remarkable speed of 28,000 km per hour. One of the key advantages of having a 3D printer in space is the ability to create essential equipment and items on-demand. This is particularly valuable since transporting cargo to the ISS requires considerable time and resources.

Creating Equipment On-Demand: 3D Printing on the ISS

The importance of 3D printing technology is well-known on Earth, where it is used to create a wide range of items and tools. However, its significance is amplified in the context of space exploration. Astronauts on the ISS can now manufacture equipment that assists them in their duties, especially during emergencies or when traditional tools malfunction. Though the instruments used on the ISS are rigorously tested and adhere to strict safety standards, the ability to 3D print equipment on-demand adds an extra layer of preparedness and helps minimize risks.

The First 3D Printed Object in Space: A Milestone Achievement

An impressive example of the technology’s impact occurred when ISS Commander Barry Wilmore needed a wrench. NASA came up with a solution by 3D printing the wrench. They first printed a sample of the wrench on Earth using the same 3D printer and then replicated it in space, achieving this remarkable feat in a four-hour session with 104 layers of printing. Notably, this marked the first time an object was designed on Earth and printed in space using 3D printing technology, a groundbreaking achievement for space manufacturing.

According to NASA, this tool will be brought back to Earth for testing and comparison with others that have been printed on Earth. The International Space Station is the only area in space where 3D printing technology may be tested to develop it and determine the differences for use in future plans, in space, such as Mars.

This is what happened later, as NASA discovered that the 3D printer that uses FDM technology works well in the absence of gravity, as there were no significant differences or obvious problems between the samples printed on Earth and in space, but NASA is now investigating how the microgravity environment may benefit how objects are designed and built-in space for parts that cannot be made on Earth. The printer created one item that would be incredibly difficult to create on the ground due to gravity’s droop.

NASA’s official website offers the file in STL format for printing. This unique piece is available for download, printing, and use by anybody. Consider printing a NASA design that has been rigorously tested to ensure its suitability for usage in space. It truly is a fantastic thing. You may get the file from here.

They also offer a Multi-Purpose Precision Maintenance Tool, which has a variety of useful tools that enable an astronaut to execute their work with comfort and convenience. The various-sized drives at the top allow the user to connect sockets. Wrenches of various sizes are arranged in the middle, allowing fewer wrenches to be transported to the job site. On the left is a precision measuring tool along with wire gauges and a single-edged wire stripper.

In the center is an outline for Velcro to be applied allowing an easy storage around the station. A circular hole in the bottom center allows for a clip to be used as well. On the right, and ergonomic grip is built into the tool with ridges for better grasp, lastly a pry bar is built into the ergonomic grip for ease of access.

It is a tool intended for astronauts on the International Space Station that is appropriate for and compatible with their work there.

You can also get it in STL format by clicking here:

Because the International Space Station contains some plastic waste, and the 3D printer requires a filament with specific specifications in order to use it in the manufacture of models and samples, NASA has found a solution to both problems at the same time, reducing the need to send the filament into space while also recycling it beneficially. It is a gadget designed by Tethers Unlimited, and it was first used there in February 2019.

Currently, NASA intends to employ 3D printers to manufacture metals or plastic materials with qualities comparable to metal that will serve the purpose, because the majority of the items needed in space are made of metal.

In terms of the first 3D printed object in space, NASA astronaut Barry “Butch” Wilmore, commander of Expedition 42 onboard the International Space Station, installed the printer on November 17, 2014, and executed the first print for a calibration test.

Based on the print test findings, the ground control team issued orders on November 20 to re-align the printer and perform a second calibration test. These tests proved that the printer was ready for production. The first created item was a front panel for the extruder casing, which was supplied by the printer’s ground control units on November 24. This demonstrated that the printer was capable of producing parts for itself.

You may download this piece, try it out for yourself, and share it with your friends along with other things from here:

NASA also has a library of excellent designs for vehicles, satellites, and space equipment that are ready for 3D printing on its official website. You may see them from here and get a one-of-a-kind experience.