what is wood filament (PLA filament)?

Wood filament is a type of 3D printing filament that is made up of a combination of PLA (polylactic acid) filament and wood particles. The wood particles typically make up around 30% of the filament and they give the printed parts a wood-like appearance.

It is important to note that during printing, some of the wood particles may burn off or be partially burned, so it’s recommended to print in a well-ventilated place.

Print Settings

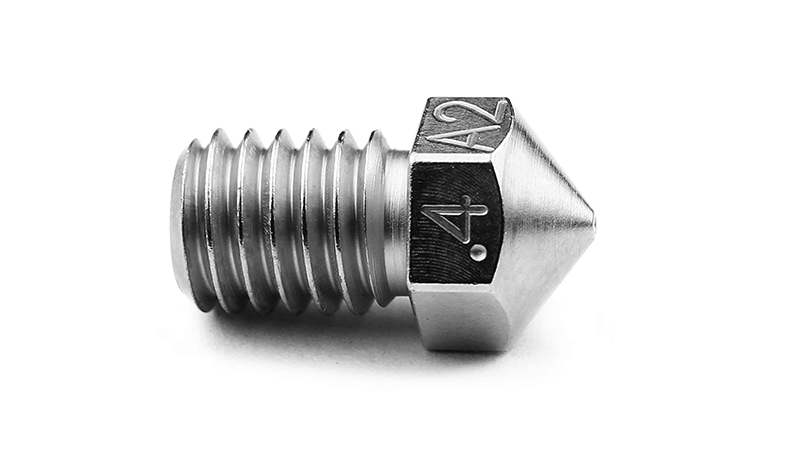

Nozzle diameter for wood filament

As previously mentioned, wood filament contains wood particles mixed in with the PLA filament. These wood particles can be abrasive and can cause clogging in the nozzle of the 3D printer. This is because the wood particles are not as fine as the plastic particles found in traditional PLA filaments. If the nozzle of the printer has a small diameter, the wood particles may not be able to pass through it easily, resulting in clogging of the nozzle. This can cause problems with the print quality and can also lead to damage to the nozzle itself.

To avoid nozzle clogging with wood particles, it is important to use a nozzle with a larger diameter. A nozzle with a diameter of 0.4 mm or more is recommended. This is because the larger diameter allows for more room for the wood particles to pass through, reducing the likelihood of clogging. Additionally, using a steel hardened nozzle instead of a brass nozzle can also help to reduce the wear and tear caused by the wood particles.

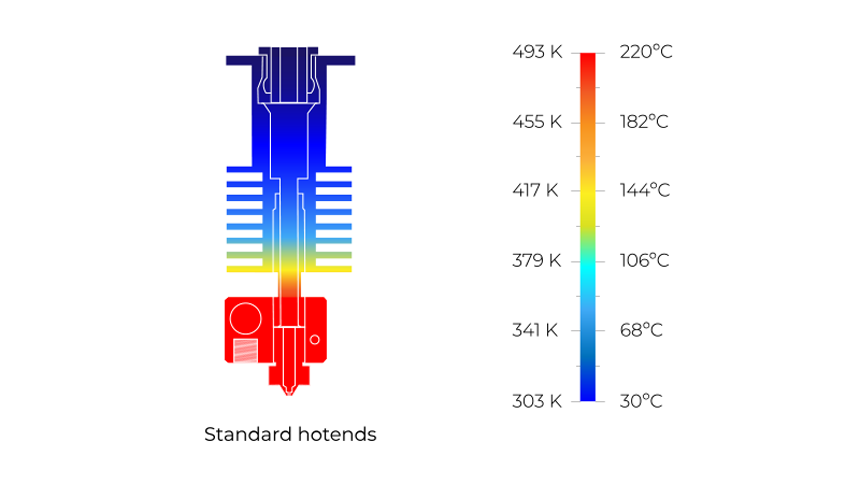

Temperature

When printing with wood filament, it is recommended to use the lowest temperature possible within the recommended range to achieve the best results. This is because using a lower temperature can help to reduce the burning off of the wood particles, which can give a better wood-like appearance to the final print. However, using a lower temperature can also cause poor layer-to-layer adhesion. To ensure good adhesion, it is recommended to print a temperature calibration tower and test the ideal temperature for the filament. The ideal temperature can differ depending on the brand of the filament, so testing the filament before starting a big print can help to ensure a successful print.

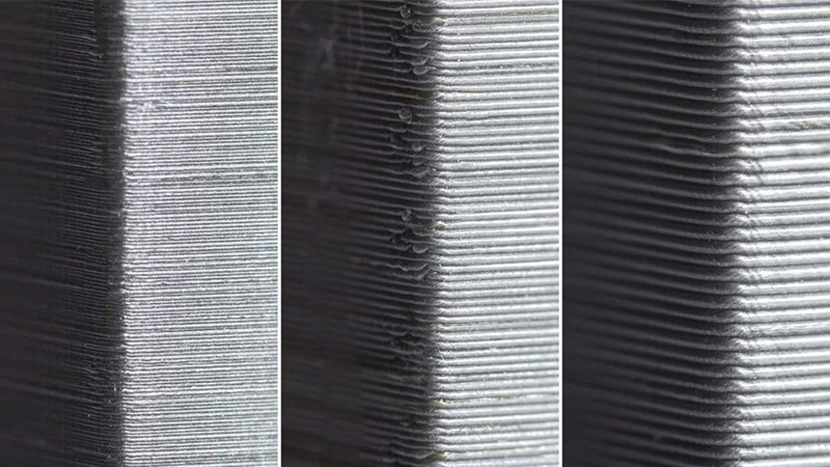

Layer Thickness during printing wood filament

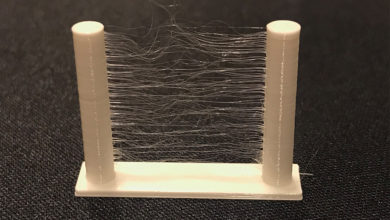

One of the advantages of using wood filament in 3D printing is that the printed layers are less visible compared to regular PLA filament. This is because the presence of wood particles in the filament helps to scatter the light and break up the sharp edges of the printed layers. This results in a more natural, organic look that closely mimics the appearance of real wood.

When printing with wood filament, it is recommended to use a nozzle with a diameter of 0.4 mm or more, as this will help to avoid clogging the nozzle with wood particles. Additionally, the layer height should be set between 0.1-0.3 mm. This range of layer height is ideal because it allows for enough material to be extruded to cover the previous layer, while still maintaining a high level of detail in the final print. With this range of layer height and nozzle size, the printed layers will not be as visible and will give you a good print, with a more natural wood-like appearance.

It’s important to note that using a lower layer height will result in a higher print resolution but also will increase the printing time and the final print will be more visible, so it’s important to find a balance between print resolution and final look.

Printing speed

When 3D printing with wood filament, it is important to control the printing speed to achieve the best results. The recommended printing speed for wood filament is 30-40 mm/s. This range of speed is ideal because it allows the filament to melt properly as it is extruded through the nozzle.

A slow printing speed is necessary because wood filament has a relatively low printing temperature compared to regular PLA filament, which means that the material takes longer to melt. If the printing speed is too fast, the filament may not have enough time to melt completely before it is extruded out of the nozzle. This can cause poor layer-to-layer adhesion, and affect the final print quality. Additionally, if the filament is not fully melted, the wood particles in the filament may not be properly distributed in the final print, which can affect the overall appearance of the print.

It’s important to note that the ideal printing speed may vary depending on the brand of the filament, and the specific printer used. So, it’s always recommended to test the filament with different printing speeds to find the ideal one that suits your printer and the filament.

layers cooling

When 3D printing with wood filament, it is important to control the cooling speed of the printer in addition to the printing speed and temperature to achieve the best results. The recommended cooling speed for wood filament is 50% or less.

A slow cooling speed is necessary because the printing speed and temperature are relatively low compared to regular PLA filament. This means that the printed layers will take longer to cool down and solidify. If the cooling speed is too fast, the layers may cool too quickly, which can cause warping, cracking, or other issues with the final print. Excessive cooling can also cause the filament to shrink too quickly which can cause the printed parts to lose its accuracy.

A cooling speed of 50% or less helps to ensure that the printed layers have enough time to cool down and solidify properly. This results in a more stable and accurate final print, with fewer issues related to warping or cracking.

It’s important to note that the ideal cooling speed may vary depending on the brand of the filament, the specific printer used and the ambient temperature of the room. So, it’s always recommended to test the filament with different cooling speeds to find the ideal one that suits your printer, the filament and the environmental conditions.

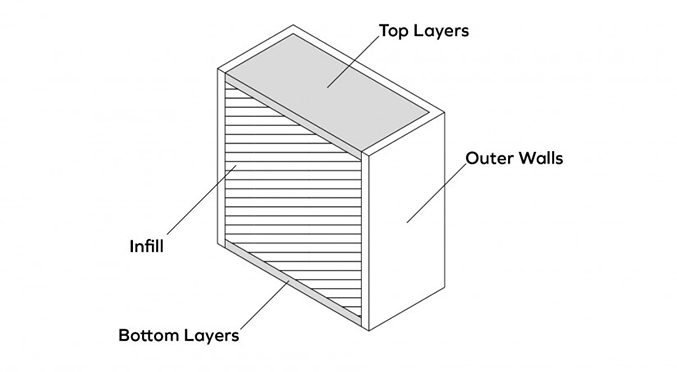

wall thickness & infill

Wood filament is slightly weaker than PLA, due to the presence of wood particles.

To overcome this problem, it is recommended that the wall thickness should not be less than 1.2 mm or 3 perimeters (0.4 mm nozzle), and with 20% infill at least

Pharaonic obelisk printed based on the settings mentioned in the article

note: These settings are approximate based on our experience and may vary slightly based on the wood filament brand.

You can purchase wood filament from here