Introduction

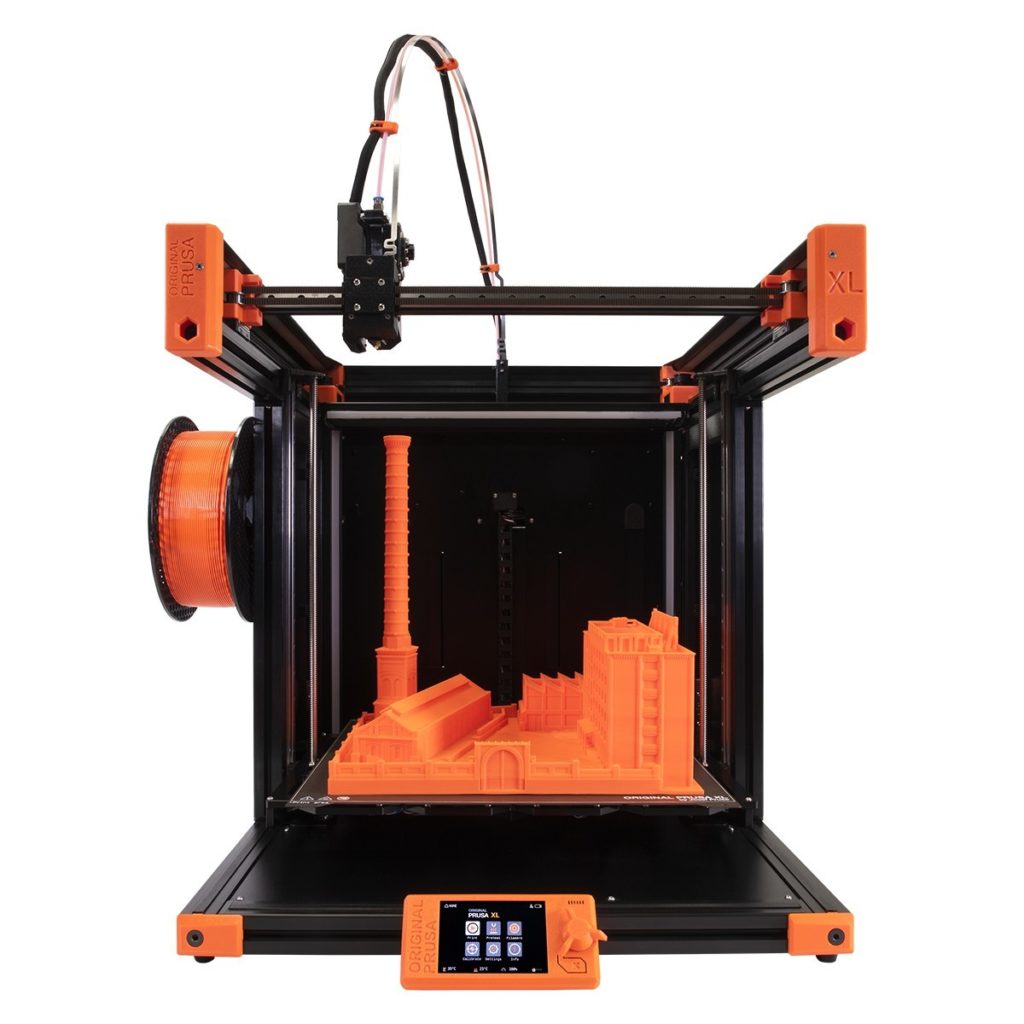

Prusa, a company founded by inventor Joseph Prusa in 2012, has created a new and innovative 3D printer that sets it apart from other competitors in the market. The Original Prusa XL printer utilizes the Core XY system for a more stable and efficient printing process and has a large build volume of 36 * 36 * 36 cm. It also includes an optional tool changer with up to 5 separate tool heads and automated first-layer calibration. The printer’s extrusion technology and modular bed design also contribute to its exceptional print quality. Prusa’s focus on providing users with dependable and high-quality 3D printers is evident in this new offering, which marks a significant advancement in 3D printing technology.

What is new?

As we have seen, this time is entirely different, not like all of the 3D printers that we use or are used to, but rather creative and current technologies that truly make the 3D printer more pleasurable, dependable, and simple.

The printer is based on the Core XY system, which is the most mechanically stable, allowing for faster printing and fewer issues. What’s new here is that the company has begun to support enormous sizes, which this mechanism requires, therefore we see the printer at 36 * 36 * 36 cm.

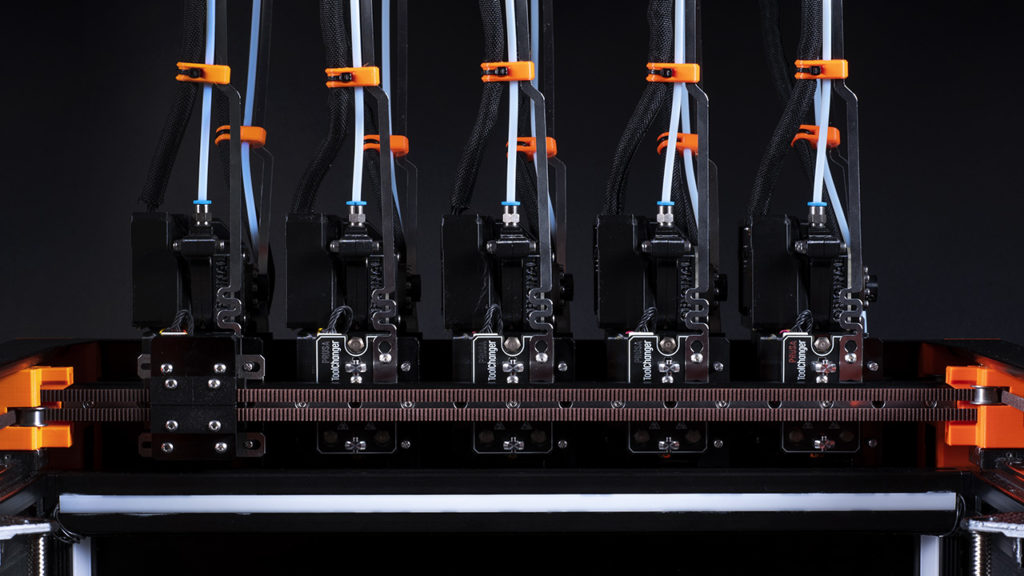

It has an optional tool changer with up to 5 separate tool heads and enables automated first-layer calibration for an always-perfect first layer, in a new, intelligent way.

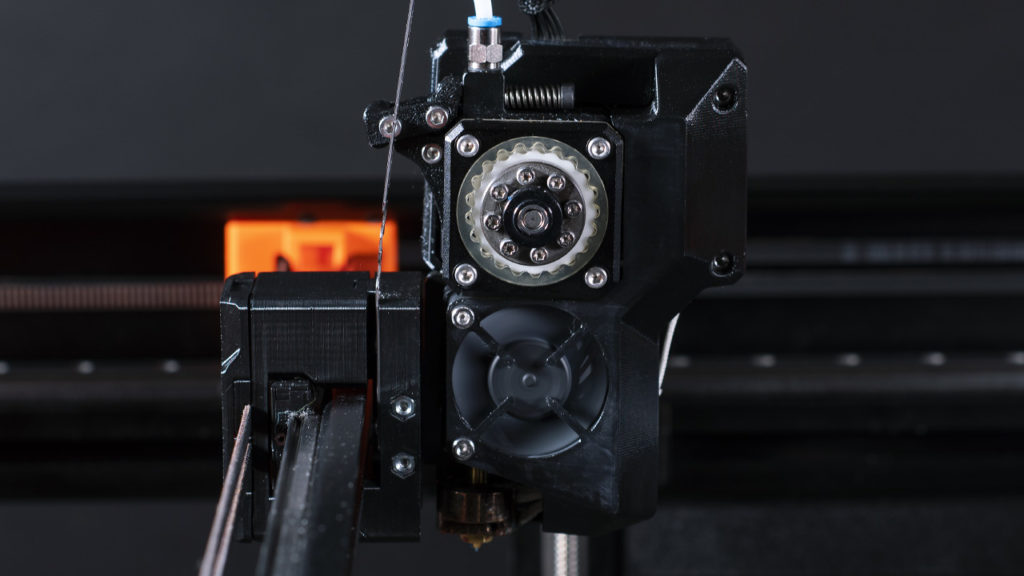

The 3D printer is completely new and has a unique and sophisticated extrusion technology, both mechanically and electronically.

Comes with the entirely redesigned “Nextruder” extruder with a zero-backlash cycloidal gearbox, hot-swappable nozzles, and a Load Cell-based technology for fully automated first-layer calibration. There is no manual calibration and no Live Z adjustments. Every time you start a print, the XL produces a beautiful initial layer across the whole surface.

Perhaps the most appealing feature of this 3D printer is that the XL can be readily expanded to up to five tool heads owing to an all-new technology high-precision tool changer with automated calibration through load cell sensor, eliminating the need for time-consuming printing calibration. Ensures that a kinematic coupler mechanism has been constructed internally. Have access to millions of hassle-free tooling modifications.

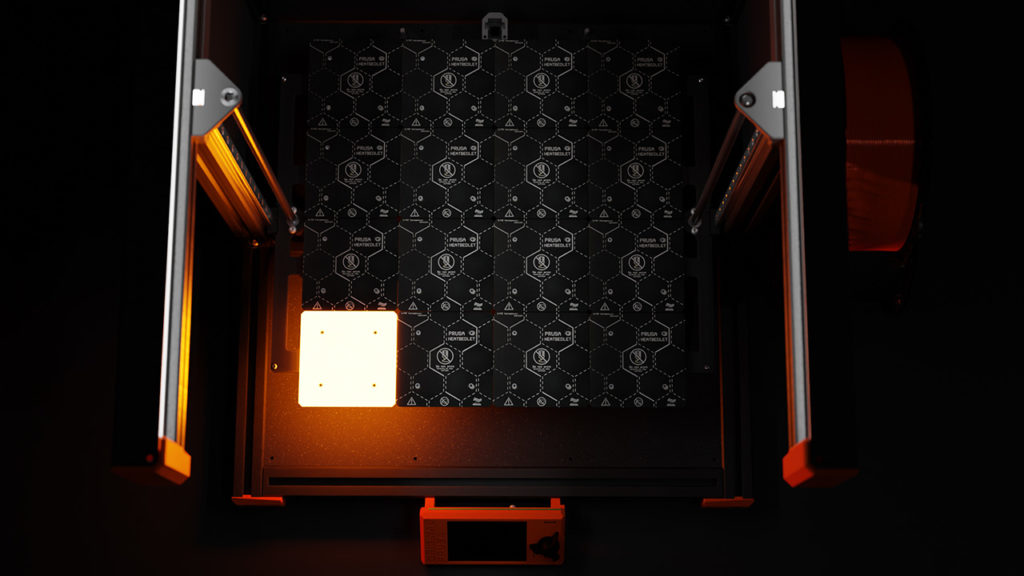

The XL’s modular bed design improves print quality even further – another first in 3D printers. The XL employs an array of tiny individually controlled portions rather than a single huge heating bed, which is prone to torsion.

When printing smaller things, just the appropriate portion of the heatbed is active to save energy, making the XL energy efficient. The XL, like other early Prusa 3D printers, employs double-sided spring steel sheets that are glued to a variety of surfaces, allowing for easy maintenance and printing removal.

New Original Prusa XL Features

Nextruder features

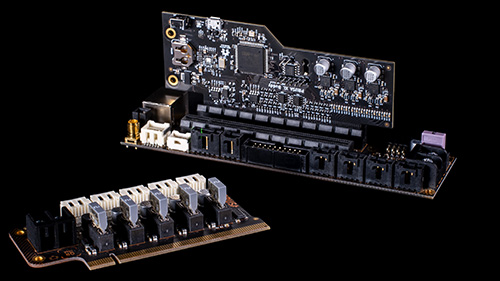

The pioneering company spared no effort in developing the XL without flipping it around. Nextruder is the name given to the latest generation of 3D printer extruders. The Nextruder is managed by a single connection cable and has integrated electronics, including a dedicated CPU and stepper motor directly into the print head. Fans, thermistors, the heater block, and the extruder motor are all directly connected to the plate inside the print head.

Because of the totally rebuilt extruder assembly, the company was able to implement fully automated first layer calibration, resulting in an always faultless first layer. The XL can measure the physical stress in the heatsink and check the print surface using an in-house designed load cell sensor incorporated into the heatsink. As a result, XL can use the load cell system to produce a highly precise height calculation for the first layer. There’s no need to re-calibrate anything if you’ve only changed the nozzle or print paper. There is no Live Z, and no manual adjustments are available. Every time you start a fresh print, the XL gives a stunningly smooth initial layer.

Two little gears are no longer used to drive the bristles. Prusa instead offers an entirely new zero-backlash gearbox (20:1) with big non-slip driving gear. This allows for more control while also improving compatibility with flexible materials. And there’s more: the nozzle and hot end may be swapped out during operation. The XL lets you remove the brand-new hot-connection assembly from the extruder without disassembling it. In addition, the business has added another thermostat to the thermal break, allowing us to adjust the temperature to material requirements and detect heat creep.

Rigid CoreXY build

The XL is designed around a strong aluminum extrusion frame, which gives it stability and rigidity. The XL produces high-quality 3D prints up to 36×36×36 cm (14.17″14.17″14.17″) with high-quality stepper motors, linear rails, and an energy-efficient heatbed with 16 independently regulated segments.

Power-loss recovery

Large prints can easily take many days to complete. You do not, however, need to be concerned about power outages. The XL has a hardware-based power-loss recovery system. In the event of a power outage, the XL remembers the last known extruder location so that when power is restored, the machine may resume precisely where it left off.

Automatic First Layer Calibration

The Load Cell feature on the Nextruder allows for entirely automated first-layer calibration with NO human participation. There are no modifications or tweaking. The XL checks the distance between the nozzle and the sheet with precise accuracy before each print, ensuring a flawless initial layer every time.

32bit electronics and smart features

The XL is driven by a new 32-bit motherboard with an extension connection, which allows for simple expansion to up to five tool heads. The XL is simple to set up and use, with popular features like one-click printing and G-code preview.

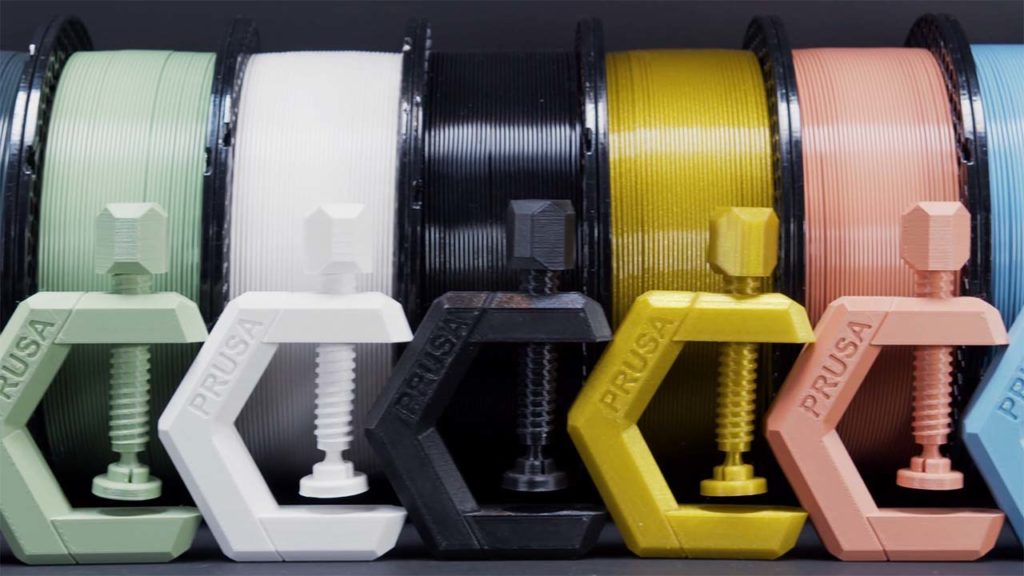

Wide range of supported materials

The XL is completely suitable with a broad variety of materials. Whether you want to print something for fun out of PLA and flexible materials, or you need to make sturdy prototypes out of PETG, ASA, Polycarbonate, and Polypropylene, the XL can handle it all.

Toolchanger

The XL may be outfitted with up to five separate print heads, each with its own electronics board. The domestically designed tool changer employs a dependable wear-resistant technology as well as completely automated tool alignment calibration, resulting in thousands of trouble-free tool changes. This allows for rapid and easy printing with numerous colors and soluble supports.

Where can you get it?

The latest 3D printer is available for pre-order from the Prusa website, click here, for $ 199 to reserve, and the full sum, $ 1,800, must be paid. The printer costs $ 1999, and when your purchase is going to be dispatched, the company will contact you to modify your order.