What is PETG material?

PETG, or Polyethylene Terephthalate Glycol, is a thermoplastic material that is derived from a modified version of Polyethylene Terephthalate (PET). The addition of Glycol, represented by the (G) in the acronym, improves the material’s properties by increasing its durability, flexibility, and 3D printing capabilities. The glycol addition allows for improved resistance to brittleness and makes it easier to shape and maintain its integrity during the 3D printing process.

Why is PETG filament used in 3D printing?

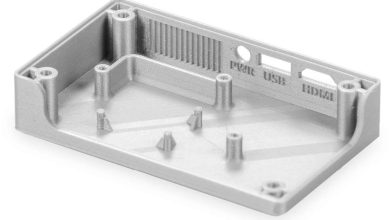

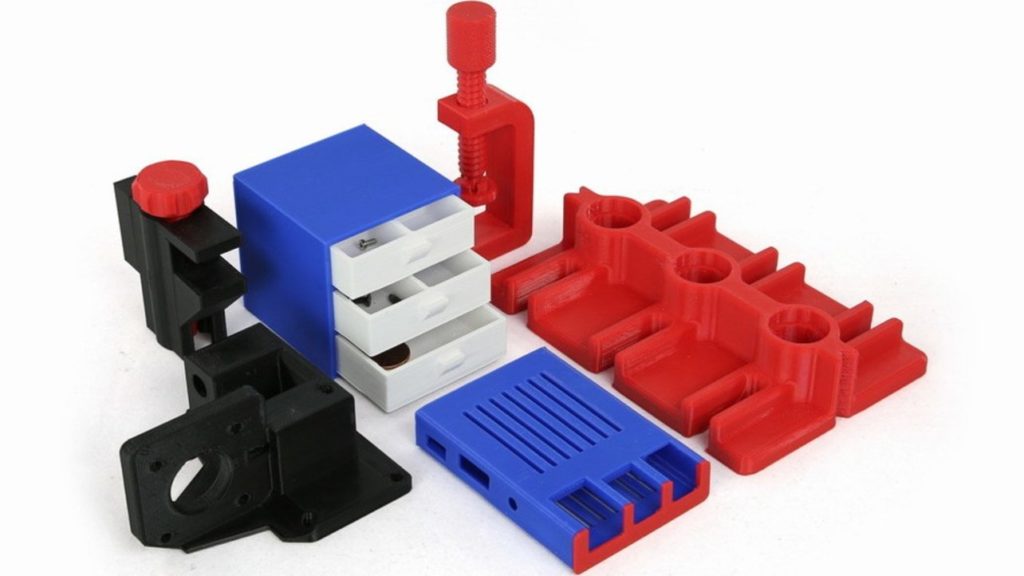

PETG filament is a popular choice among 3D printing enthusiasts and professionals alike. It has properties that make it easy to print, similar to PLA filament, but also has additional characteristics that make it suitable for a wide range of applications. These properties include high mechanical strength, resistance to heat, moisture, and some chemicals, and minimal warping during the printing process. These advantageous properties make it an ideal choice for engineers and manufacturers when printing prototypes, electronic parts, and some mechanical parts that are used in various designs. The Prusa 3D printers, for example, use PETG filament to print parts.

Advantages:

Relatively easy to 3D print

Compared to ABS, PETG is relatively easy to 3D print as it has low warping properties, this means that it does not require an enclosure during the printing process. However, to achieve optimal results, a high-temperature nozzle (250 °C) is necessary to properly melt the filament and a heated bed is also required to maintain the filament’s shape and prevent warping.

Temperature resistance

PETG is a material that can withstand high temperatures, which means it can be used to print parts that will be exposed to temperatures up to 80 °C without losing its structural integrity Unlike PLA filament, which becomes soft when exposed to the sun.

Humidity resistance

One of its most important features is its resistance to humidity.

Humidity causes some printing issues. When moisture is absorbed by the filament, it is stored in the form of water molecules. When the temperature of the filament inside the nozzle rises, the water evaporates, causing gaps in the printed part and stinging issues.

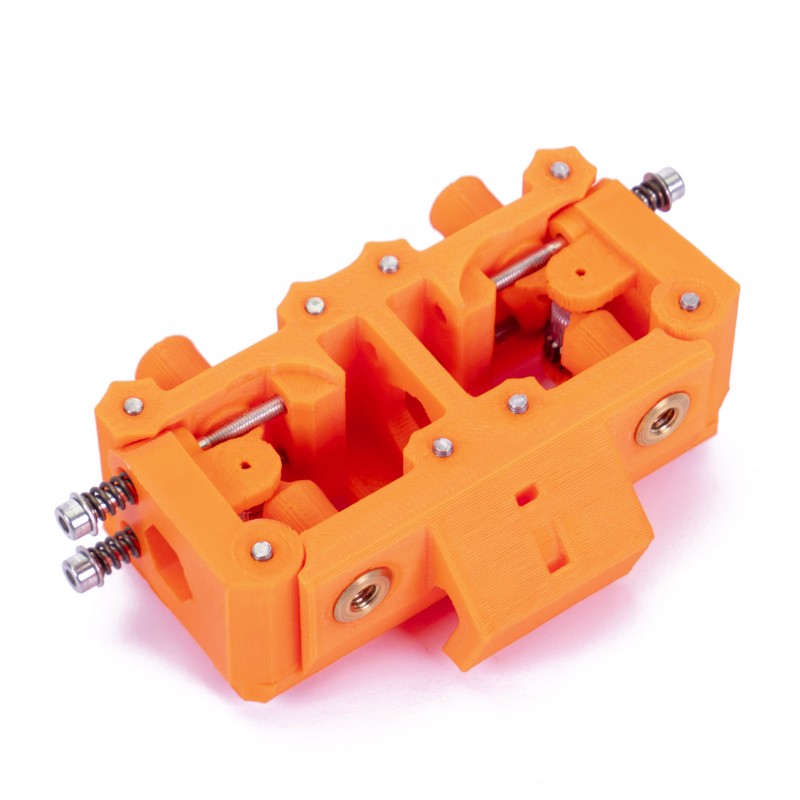

Good for printing mechanical parts

PETG filament is suitable for printing mechanical parts because it offers a good balance of properties that are beneficial for such applications. Specifically, it has relatively good resistance to mechanical stresses, which means that it can withstand external forces such as pressure, tension and bending without breaking or cracking. Additionally, it also has good heat resistance, which means that it can maintain its structural integrity and properties even when exposed to high temperatures. This combination of properties makes it a suitable choice for printing mechanical parts that will be used in a variety of applications. This includes parts that will be subjected to external forces and/or high temperatures, and still maintain its integrity and function effectively.

Chemical Resistant

PETG filament is known for its high chemical resistance which makes it an ideal material for printing protective covers and casings for parts that are exposed to various chemicals. The chemical resistance property of the filament ensures that it can withstand harsh environments and maintain its structural integrity, even when in contact with different types of chemicals. This makes it a suitable choice for printing parts that need protection from chemical exposure, such as chemical containers, laboratory equipment, and other industrial applications. Additionally, the chemical resistance properties also make it a suitable material for printing parts that are used in harsh environments or conditions, where chemical exposure is a possibility. This allows for parts to be printed with PETG filament that will be able to maintain its properties and function effectively, even when exposed to chemicals.

Disadvantages:

High stringing

Stringing is a common issue that occurs while 3D printing with PETG filament. It is characterized by the presence of thin, hair-like strands of filament that are located in the path of movement of the nozzle as it moves from one point to another on the printed part. This issue is caused by the tendency of the filament to ooze out of the nozzle when the printing temperature is high. The high temperature causes the filament to become more fluid and causes it to extrude even when the nozzle is not actively printing. This extruded material then solidifies as it cools and forms the thin, hair-like strands of filament that are referred to as stringing. This problem can be reduced by adjusting the printing temperature, retraction settings, and other slicer settings to minimize the amount of filament that oozes out of the nozzle.

Poor bridging

Printing with PETG filament requires high temperatures, which can make creating bridges in printed parts challenging. A bridge is an overhang or unsupported area that requires the filament to be extruded while the nozzle is in motion. PETG’s high printing temperature can make the filament excessively fluid, making it difficult to maintain a consistent flow and shape as it is extruded. This can lead to bridge collapse or poor quality.

o overcome this challenge, one approach is to increase the cooling fan speed to cool the filament quickly and lower the printing temperature. This will make the filament more viscous, thus easier to shape and control during printing. However, lowering the printing temperature can weaken the bond between layers, compromising the structural integrity of the printed part. Finding the right balance between cooling and printing temperatures is crucial to achieve optimal results.

The supports are difficult to remove

PETG filament is known for its strong layer-to-layer adhesion properties, which can make it challenging to remove supports from the printed part. Support structures are added to a 3D model to provide support for overhanging or unsupported areas during printing. They are typically removed after printing.

However, because of the strong adhesion properties of PETG, the supports tend to adhere to the printed part more firmly than with other materials. This can make it difficult to remove the supports without damaging the printed part. To overcome this problem, it is important to carefully tune the support settings, particularly the support z distance. This refers to the distance between the support structure and the printed part. Increasing the distance between the two can help to reduce the adhesion strength between the supports and the printed part, making it easier to remove the supports without damaging the part. Additionally, using a support removal tool or using a gentle force to remove the supports can also help to reduce the risk of damaging the printed part.

Recommended print settings

| Hot end | (230-250)°C |

| Heat bed | (70-100)°C |

| Printing speed | (40-60) mm/s |

| Outer wall speed | (20-30) mm/s |

| Initial layer height | (0.2-0.3) mm |

| Initial layer speed | (15-25) mm |

| Retraction distance | (2-6) mm |

| Retraction speed | (25-35) mm/s |

| Combing mode | All |

| Support pattern | lines/zig zag |

| Support Z distance | (0.1-0.2) mm |

| Support X/Y distance | (0.8-1) mm |

Note: All the settings mentioned in this article are based on the Cura slicer. The printing settings are only guidelines for printing with PETG filament successfully. It is recommended that you do your own testing to adapt these settings to the specific needs of each design.